| CAT. No. | LUBF-90 | LUBF-170 | LUBF-290 | LUBF-350 | |

| LUBF-90G | LUBF-170G | LUBF-290G | LUBF-350G | ||

| LUBF-90P | LUBF-170P | LUBF-290P | LUBF-350P | ||

| LUBF-90GP | LUBF-170GP | LUBF-290GP | LUBF-350GP | ||

| Temperature Range (°C) | -40 to -80.0 | ||||

| Accuracy (°C) | ± 1.0 | ||||

| Uniformity (°C) | ± 5.0 | ||||

| Control system | Micro control / PLC | ||||

| Volume ( Liters ) | 90 | 170 | 290 | 350 | |

| Trays | 2 | 3 | 3 | 4 | |

| Power (W) | 400 | 600 | 750 | 1000 | |

| Voltage (VAC) | 230 , 50/ 60Hz | ||||

| DIMENSIONS (W X D X H ) IN CM AND WEIGHT (KG) | |||||

| Inner Size | 42x38x57 | 49x42x85 | 58x50x102 | 58x57x106 | |

| External Size | 67x71x141 | 75x76x169 | 83x83x190 | 83x90x197 | |

| Size with packing | 82x86x156 | 90x91x184 | 98x98x205 | 98x105x212 | |

| Net Weight | 125 | 150 | 175 | 225 | |

| Gross weight | 150 | 200 | 225 | 250 | |

NB:

P- Models are with Programmable logic control (PLC)

G- Models are made out of Stainless steel 304 (GMP)

Temperature Data Scanners

8 /16 Channel programmable temperature Data Scanner for record, store and print the data online and off line with variable print time intervals, suitable for 80 col. Dot matrix printer.

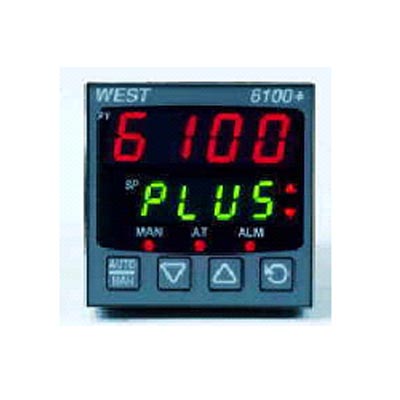

PLC system

Programmable Logic Control with Safety controller, auto changeover of Standby systems & other event managements With 4.3” Color HMI with touch screen, Ethernet connectivity and security lock for prevention of unauthorized tampering.

PC interface

communication Micro controller based PID controller to record, store and print the set values, process values, Date & time with variable print time intervals with RS-485 communications for PC interface.

Software

LABTOP “DATALINX” CFR 21 Part 11 compliance communication software for data management. Complete with RS- 485 multi dropping to monitor multiple chambers to one software.

Mobile alert

Mobile alert via GSM Technology in case of system failure.

Power Backup

Uninterrupted online power supply for PLC in case of power failure.

Trays

Additional tray suitable for above equipment as per your requirement.

Door access

Biometric magnetic door access for secured door opening with software to maintain log record

Calibration

The equipment is calibrated with the help of master calibrator, which is certified for its accuracy by Electronics Regional Testing Laboratory (ERTL West) Government of India recognized testing laboratory with reference to National Physical Laboratories (NPL).

Documentation

For GMP complaint models LABTOP offers IQ, OQ and PQ validation with documentation, reports, calibration and test certificates.

Service and Support

The training undertaken by our Channel partners and engineers is of the highest standard in the industry, ensuring that our customers are supported by the highest level of technical expertise and as such can be assured that their equipment will perform to the standards required at all times.

Our wide network of Engineers/Technicians enables us to respond to any technical query, ensuring that our customers receive the maximum benefit from their equipment.

NB: Specifications are subject to change without prior notice.

Copyright @ 2024 Labtop Instruments Pvt . Ltd . All rights reserved.